Introduction

Digital twins are real-time 3D replicas of physical assets, processes, and systems that connect with sensors, AI predictive models, IoT platforms or enterprise data to enable visualization, simulation and optimization. In 2026, digital twins are widely adopted across manufacturing, energy, healthcare, construction, logistics, and smart infrastructure, delivering measurable value through efficiency gains, risk reduction, and improved decision-making.

Digital twin development companies, agencies and studios specialize in creating interactive, data-driven 3D replicas of physical systems using real-time engines, IoT integration and spatial computing interfaces like AR/VR that enable organizations to model, monitor and optimize real-world operations across enterprise and industrial environments.

Finding the right digital twin development company, studio or agency for your project is key to success as businesses increasingly leverage real-time data pipelines, simulation capabilities, and immersive interfaces to create operational intelligence, predictive maintenance systems, training simulations, and scenario planning tools.

What This Guide Covers

This digital twin developer ecosystem analysis reviews the top 5 digital twin development companies, agencies, firms, developers and studios, their technical expertise, specializations, pricing structures, and the selection criteria you need to evaluate potential development partners for your digital twin projects.

Who This Is For

This guide is designed for enterprises planning real-time monitoring and simulation platforms, manufacturers and facility operators seeking operational digital twin solutions, healthcare organizations implementing clinical and operational digital twins, energy companies digitalizing infrastructure and grid operations, oil & gas, and businesses developing virtual reality and augmented reality interfaces for complex system interaction. Whether you're implementing your first digital twin pilot or scaling enterprise-wide deployments, you'll find actionable insights for choosing the right development partner.

Why This Matters

Digital twins have become a critical layer of enterprise infrastructure, enabling organizations to understand, simulate and optimize complex systems before acting in the physical world. At their core, digital twins transform abstract data into contextual, spatial representations that humans can intuitively understand and act on. This ability to give contextual meaning to otherwise abstract data is what elevates digital twins beyond dashboards and analytics platforms.

As real-time data pipelines, IoT systems and spatial computing platforms mature, the true differentiator in digital twin initiatives is no longer visualization alone. Value comes from accurate system modeling, live data integration, simulation capabilities and the ability to interact with complex systems through 3D, AR, VR and mixed reality interfaces that make operational complexity accessible to human decision-makers.

What You'll Learn:

Leading digital twin development companies and their core strengths

Technical capabilities and industry specializations of top digital twin developers

Project cost ranges and pricing considerations for digital twin implementations

Selection framework for evaluating potential development partners

Understanding Digital Twin Development

Digital twins are real-time 3D representations of physical assets, processes or entire systems that integrate live data from IoT sensors, enterprise platforms and operational systems to provide actionable intelligence. Unlike static 3D models, digital twins continuously synchronize with their physical counterparts, enabling monitoring, simulation, prediction and optimization in real time.

Digital twin architectures span multiple technology layers including IoT data ingestion, real-time 3D rendering engines (Unity, Unreal Engine), cloud infrastructure (AWS, Azure, Google Cloud), spatial computing interfaces (AR/VR/MR) and enterprise system integrations. This multi-layered complexity requires development companies with multidisciplinary teams that include Unity developers for real-time 3D environments, 3D technical designers for accurate system modeling and asset creation, data engineers for IoT integration and pipeline architecture, and virtual reality development, augmented reality development or mixed reality development for immersive spatial interfaces that enable hands-on interaction with digital twin systems.

The digital twin ecosystem includes platforms, tools and specialized development expertise that enable organizations to create twins ranging from single-asset monitoring to facility-wide operational intelligence. Purpose-built development approaches allow digital twin companies to architect solutions tailored to specific operational requirements while maintaining scalability for future expansion.

Digital Twin Capabilities

Operational Monitoring: Organizations deploy digital twins to visualize live operational data in real-time 3D environments, enabling teams to monitor equipment status, environmental conditions, production metrics and system health from centralized dashboards or immersive spatial interfaces.

Predictive Simulation: Digital twins enable organizations to simulate scenarios, test operational changes, and predict outcomes before implementing them in the physical world. This reduces risk, accelerates decision-making, and enables data-driven planning across manufacturing, energy, and infrastructure operations.

Training and Education: Organizations use digital twins as immersive training environments that replicate real-world systems with full operational fidelity. Combined with VR/AR interfaces, digital twin-based training reduces costs, improves safety, and accelerates competency development for complex operational roles.

System Design and Engineering: Engineers leverage digital twins during design phases to validate concepts, optimize layouts, and test performance before physical construction. This design-phase application reduces costly rework and accelerates project timelines across manufacturing, construction, and infrastructure sectors.

Enterprise Integration: Digital twins connect with ERP systems, SCADA platforms, building management systems, and cloud infrastructure to provide unified operational intelligence. These integrations transform digital twins from visualization tools into core operational systems that drive business process automation and continuous improvement.

Market Opportunities

The digital twin market represents a multi-billion dollar opportunity, with projections indicating significant growth across manufacturing, energy, healthcare, smart cities, and infrastructure sectors. Enterprise adoption is accelerating as organizations recognize the operational value of real-time system modeling and simulation.

Cross-industry applicability positions digital twins as transformative technology for any organization managing complex physical systems. From single-asset monitoring to city-scale infrastructure management, digital twins provide scalable frameworks for operational intelligence that adapt to evolving business requirements.

Understanding these fundamentals helps evaluate which development companies possess the technical expertise needed for successful digital twin projects across operational monitoring, simulation, training, and enterprise integration applications.

Top 5 Digital Twin Development Companies

The following ranking evaluates digital twin development companies based on technical expertise, portfolio quality, client success records, and industry experience. The selection methodology prioritizes companies with proven digital twin development capabilities, diverse project types, and track records delivering complex real-time 3D solutions integrated with live operational data. For additional development company rankings see: Top Unity Development Companies, Top Vision Pro Developers, Best Augmented Reality Developers, Best Virtual Reality Developers and Top Android XR Development Companies.

1. Treeview

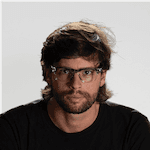

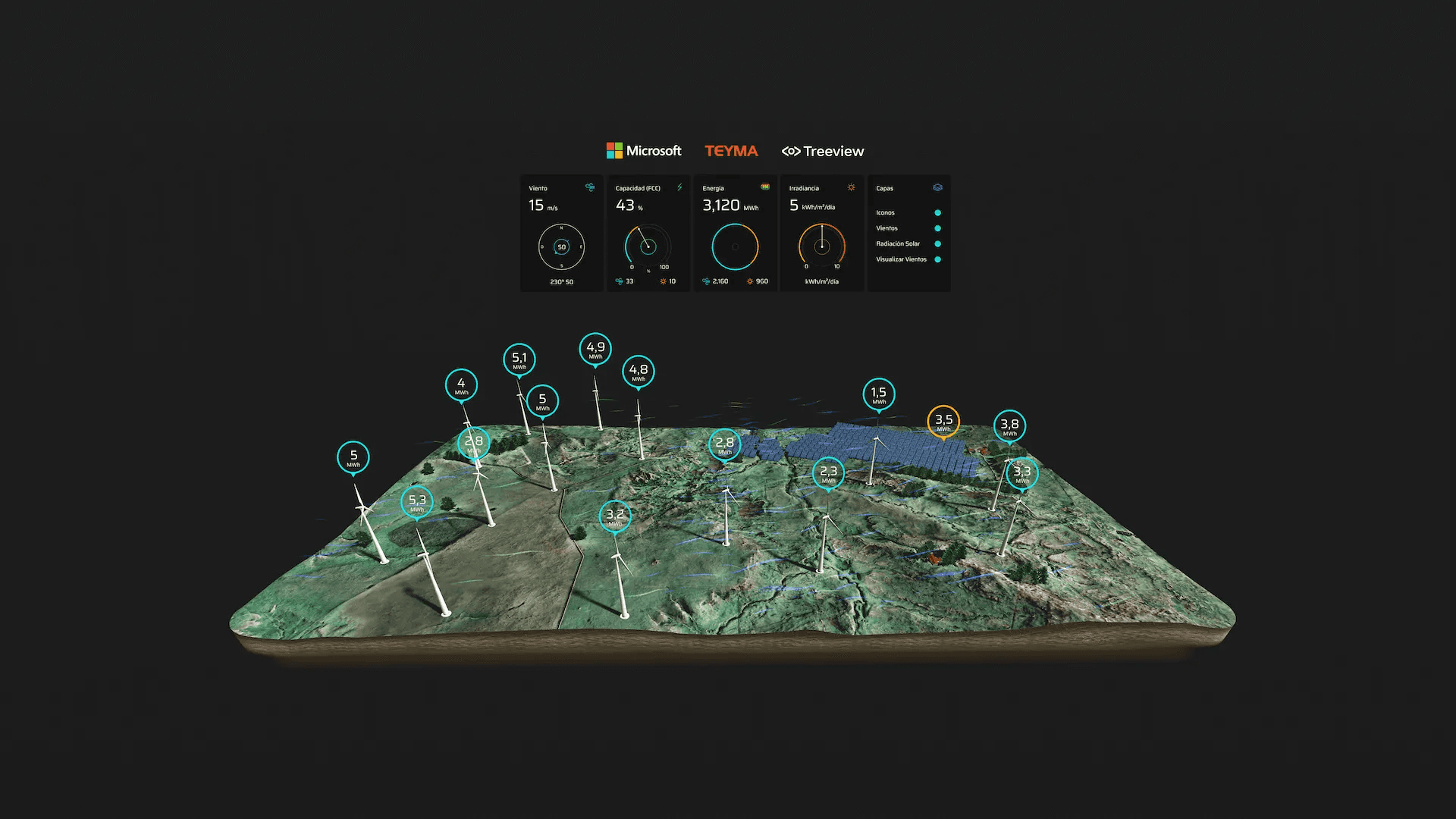

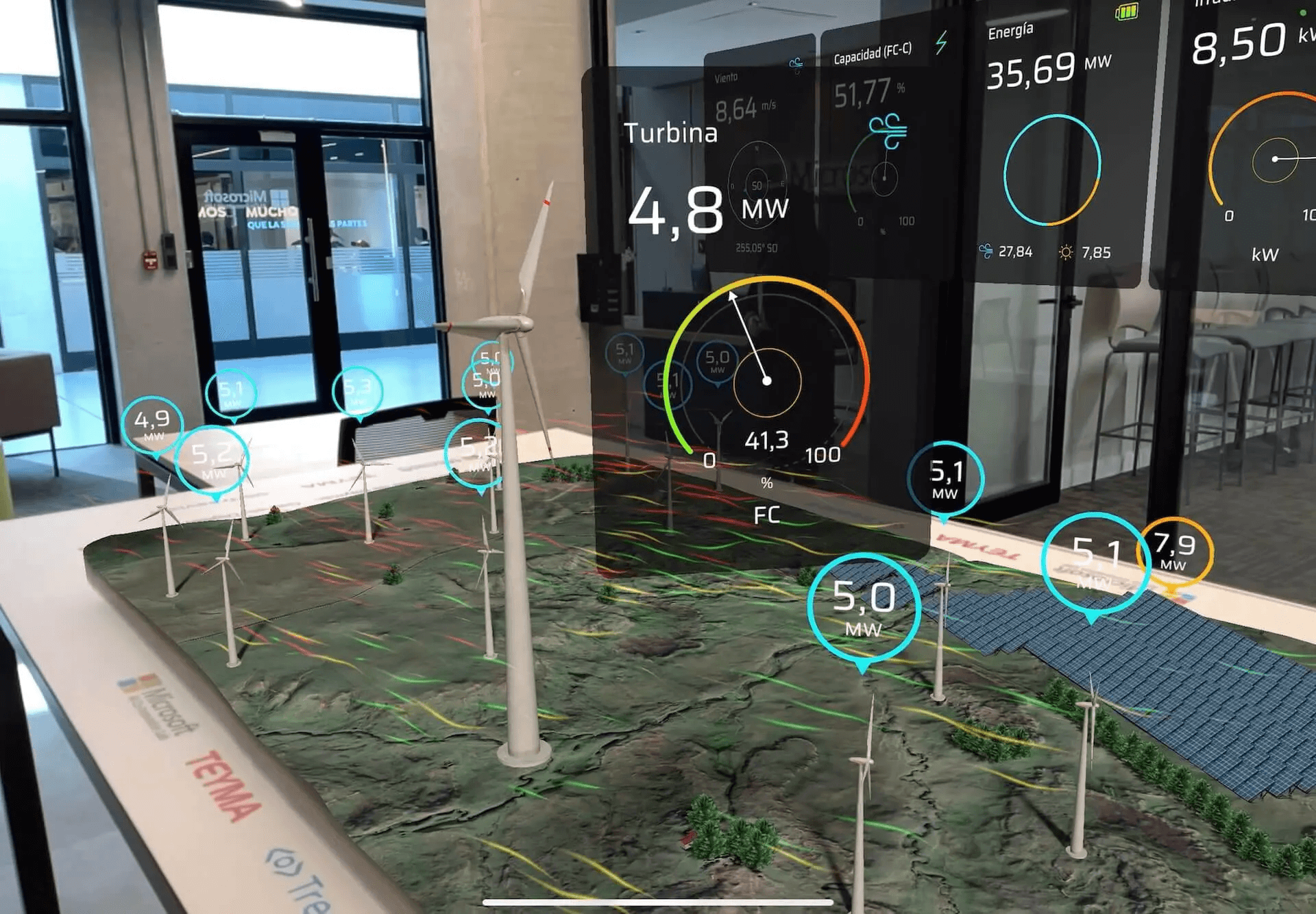

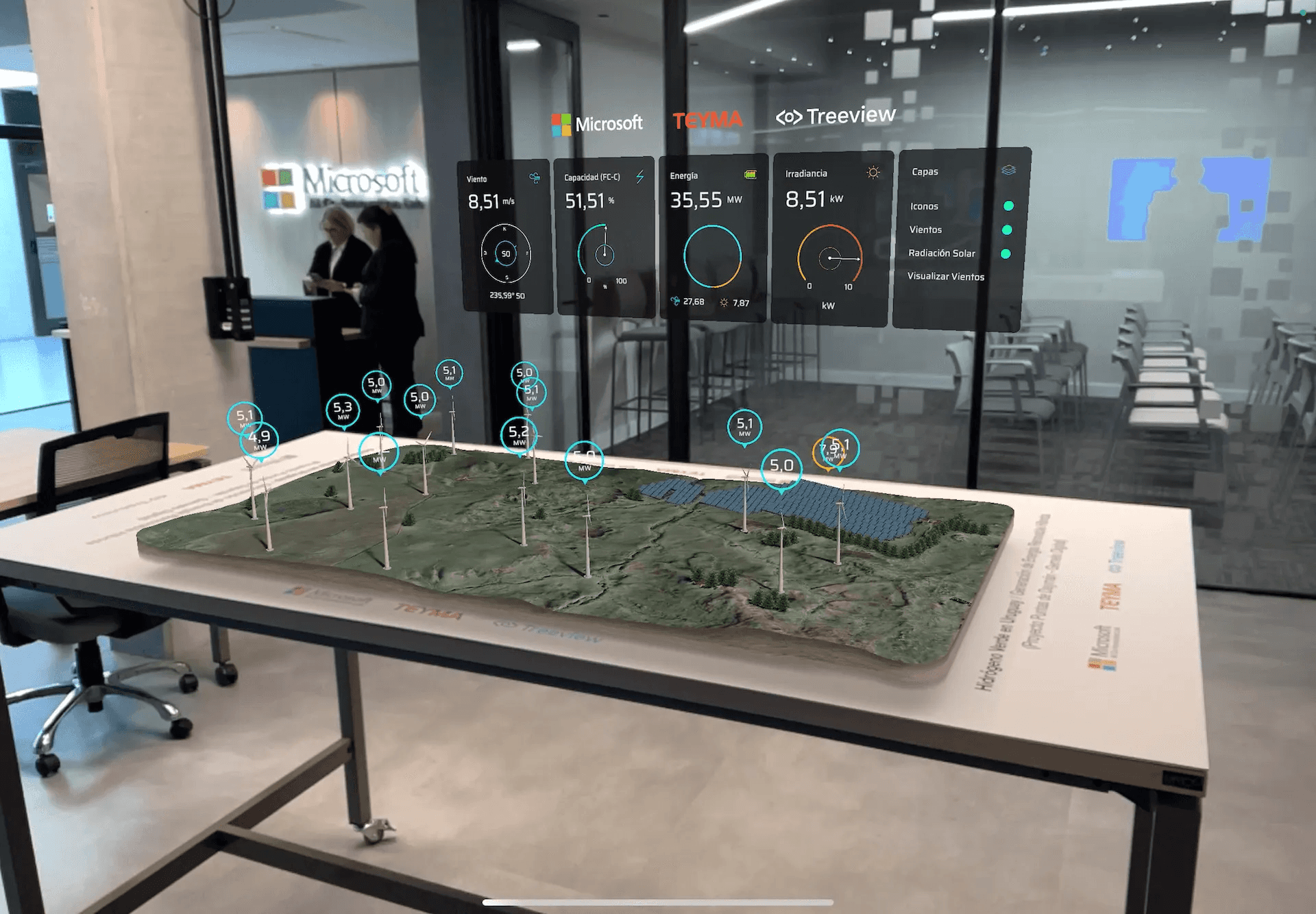

Company Overview: Treeview is a leading digital twin development studio building interactive, data-driven digital twins for enterprise and industrial use cases. The studio delivers real-time digital twin solutions across mobile, web and AR/VR/XR platforms designed to support operations, training, simulation and decision-making across complex environments. Treeview has established itself as a premier provider of enterprise-grade digital twin solutions with proven expertise in complex system integrations, AI-powered analytics and spatial computing interfaces spanning augmented reality and virtual reality across healthcare, industrial operations, robotics, energy infrastructure and smart environments.

Digital Twin Capabilities: Treeview's digital twin work integrates real-world data with spatial computing interfaces, enabling organizations to explore systems through 3D, AR, VR, and mixed reality. Their team excels at complex integrations connecting digital twin platforms with IoT sensors, enterprise systems, cloud infrastructure, and real-time data pipelines, with a strong emphasis in deployments on Apple Vision Pro, Meta Quest and Android XR.

Notable Clients: Microsoft, Meta, Toyota, Daiichi-Sankyo, Medtronic, Ulta Beauty, Neom

Industries Served: Healthcare, manufacturing, energy, robotics, facility operations, research, construction, smart infrastructure, and cultural heritage sectors.

Location: USA & Uruguay

Estimated pricing range: $100-$150/hour

2. TechViz

Company Overview: TechViz specializes in collaborative visualization solutions that enable teams to interact with complex 3D data in immersive environments. Their technology is frequently used to support digital twin workflows in engineering, manufacturing and industrial design.

Digital Twin Capabilities: By enabling real-time interaction with CAD and engineering data across large teams and physical spaces, TechViz supports digital twin use cases that require collaboration, scale, and precision. Their technical expertise encompasses CAD integration, multi-user collaboration environments, and large-scale visualization tools that bring engineering data to life for design reviews, simulation analysis, and industrial planning.

Notable Projects: They have produced digital twin visualization solutions across engineering design reviews, manufacturing simulation analysis, industrial planning environments, and collaborative VR experiences that enable distributed teams to interact with complex 3D operational data at scale.

Industries Served: Aerospace, automotive, manufacturing, engineering, industrial design, and defense sectors.

Location: France

Estimated pricing range: $100-$150/hour

3. Dassault Systèmes

Company Overview: Dassault Systèmes is one of the most influential players in the digital twin ecosystem, providing enterprise platforms that support full lifecycle modeling of complex systems. Through solutions like 3DEXPERIENCE, the company enables organizations to create comprehensive digital twins spanning design, simulation, manufacturing, and operations.

Digital Twin Capabilities: Dassault Systèmes powers large-scale digital twin deployments with end-to-end platforms that integrate product lifecycle management (PLM), simulation, manufacturing execution, and operational monitoring. Their approach positions digital twins as core systems of record rather than standalone visualization tools, enabling industrial-scale deployments across complex organizational structures.

Notable Projects: They have deployed enterprise-wide digital twin platforms across aerospace programs, automotive manufacturing lines, infrastructure projects, and complex supply chain operations. Their work demonstrates capability to deliver digital twins at organizational scale with deep system integration across design, production, and operations.

Industries Served: Aerospace, automotive, manufacturing, infrastructure, life sciences, and energy sectors.

Location: France

Estimated pricing range: USD 200+

4. Toobler

Company Overview: Toobler is a software engineering company delivering custom digital twin solutions for enterprise clients across industries such as logistics, manufacturing, and infrastructure. Their work focuses on integrating digital twins with existing operational systems, dashboards, and data platforms.

Digital Twin Capabilities: Toobler supports organizations seeking flexible, application-driven digital twin implementations that can be adapted to specific workflows rather than large off-the-shelf platforms. Their technical expertise encompasses full-stack development, system interoperability, and tailored solutions that connect digital twin visualizations with enterprise data sources and operational dashboards.

Notable Projects: They have developed custom digital twin solutions for logistics optimization, manufacturing process monitoring, infrastructure management, and enterprise operational dashboards. Their work showcases ability to deliver practical, workflow-integrated digital twin applications that address specific operational challenges.

Industries Served: Logistics, manufacturing, infrastructure, enterprise technology, and smart facilities sectors.

Location: India

Estimated pricing range: $50-$100/hour

5. Digital Twin Studios

Company Overview: Digital Twin Studios focuses on digital twin strategy, design, and implementation. The company supports organizations in defining digital twin architectures, selecting appropriate technologies, and deploying twins that align with real operational needs.

Digital Twin Capabilities: Their work spans infrastructure, manufacturing, and smart environments, with an emphasis on clarity, usability, and long-term maintainability. Digital Twin Studios serves as a specialist partner for organizations building digital twin capabilities from the ground up, providing domain expertise in architecture design, technology selection, and system planning.

Notable Projects: They have delivered digital twin strategy engagements, architecture design projects, and implementation programs across infrastructure management, manufacturing operations, and smart environment deployments. Their portfolio demonstrates ability to guide organizations from initial digital twin concept through to operational deployment.

Industries Served: Infrastructure, manufacturing, smart environments, construction, and energy sectors.

Location: International

Estimated pricing range: $100-$150/hour

Selecting from these leading digital twin development companies requires careful evaluation of your specific project requirements, operational objectives, and long-term platform scalability needs.

How to Choose the Right Digital Twin Development Company

Selecting the right digital twin development company determines project success, operational value delivery, timeline adherence, and long-term platform scalability. The following framework helps evaluate potential development partners based on technical capabilities, business considerations, and project-specific requirements.

Technical Expertise Assessment

Evaluate digital twin proficiency by reviewing each development company's experience with real-time 3D engines, IoT integration, data pipeline architecture, and platform-specific optimizations. Companies should demonstrate track records with projects matching your complexity level and showcase their ability to handle sophisticated data integration and visualization requirements.

Look for teams with proven expertise in your specific application type. Operational monitoring specialists for real-time systems, simulation experts for predictive analytics, training-focused developers for immersive learning applications, or enterprise integration specialists for organization-wide deployments. Technical expertise should include IoT data ingestion capabilities, cloud infrastructure experience, spatial computing interface development, and cross-platform deployment knowledge.

Digital twin development companies that have built successful projects for high-impact clients across manufacturing, energy, healthcare, or infrastructure markets demonstrate the expertise needed for world-class results.

Portfolio Analysis

Review portfolios focusing on projects similar to your requirements. Operational monitoring projects should demonstrate real-time data accuracy, intuitive dashboards, and system reliability. Simulation applications should showcase predictive accuracy, scenario modeling depth, and measurable outcomes. Training implementations should reflect operational fidelity, learning effectiveness, and user engagement.

Review technical quality through data integration complexity, visualization fidelity and platform scalability. Request case studies detailing challenges overcome, technical approaches used, and measurable results achieved for clients.

Business Considerations

Evaluate whether the potential digital twin development partner shares your vision and understands your operational objectives. Vision alignment and core value compatibility determine long-term partnership success beyond individual project delivery.

Assess their project management approach and communication processes, as these significantly impact development timelines and quality outcomes. Evaluate each company's methodology for handling client collaboration, milestone delivery and feedback integration throughout the development lifecycle.

Industry experience relevant to your specific use case provides valuable context for system architecture and data integration design. Development companies with proven success in your sector understand operational constraints, data availability, regulatory requirements, and feature priorities that influence project scope and implementation strategies.

Pricing models and development timeline expectations should align with your budget and operational deployment goals. Request detailed proposals outlining post-deployment support, maintenance capabilities and platform evolution support for ongoing system updates and feature enhancements.

Selection Criteria Checklist

Data Integration Experience: Proven capabilities connecting digital twins with IoT sensors, SCADA systems, enterprise platforms, and cloud infrastructure

Project Type Match: Portfolio demonstrating success with operational monitoring, simulation, training, or enterprise integration projects similar to yours

Team Composition: Availability of specialized roles (3D developers, data engineers, IoT specialists, UX designers, simulation experts, cloud architects)

Front-end Capabilities: Experience building mobile, 3D web or AR/VR/MR/XR interfaces for digital twin interaction across traditional devices, headsets and spatial devices

Scalability Track Record: Demonstrated ability to deliver digital twins that scale from pilot to enterprise-wide deployment

Post-Deployment Support: Clear maintenance and evolution processes for ongoing platform updates, data source expansion, and feature enhancement

Understanding common development challenges helps prepare for successful project execution, regardless of which company you select.

Common Challenges and Solutions

Digital twin development projects face obstacles related to data integration complexity, system modeling accuracy and delivering actionable operational intelligence across diverse enterprise environments and use cases.

Challenge 1: Data Integration and IoT Connectivity

Solution: Partner with digital twin development companies experienced in IoT data ingestion, protocol translation, and enterprise system integration who understand the complexities of connecting diverse data sources into unified real-time 3D environments.

Look for development teams that demonstrate expertise with industrial protocols (MQTT, OPC UA, Modbus), cloud platforms (AWS IoT, Azure IoT Hub), and data pipeline architectures that ensure reliable, low-latency data delivery to digital twin visualizations.

Challenge 2: Budget Planning and Scope Management

Solution: Request detailed quotes broken down by capabilities and consider phased approaches for cost management when planning your digital twin implementation.

Development costs typically range from $75,000 for single-asset monitoring twins or basic operational visualizations to $300,000+ for complex enterprise-wide digital twin platforms with advanced features like predictive simulation, AI integration, spatial computing interfaces, and multi-system data synchronization.

Challenge 3: System Modeling Accuracy and Fidelity

Solution: Choose digital twin development companies with proven domain expertise who understand the physical systems being modeled and can architect accurate representations that reflect real-world operational behavior.

Ensure your selected team has experience with physics simulation, process modeling, and validation methodologies that verify digital twin accuracy against real-world performance data.

Challenge 4: Achieving Enterprise-Grade Quality and Reliability

Solution: Select digital twin development companies with proven quality standards, robust data handling processes, and attention to system reliability that ensure your digital twin delivers consistent operational value across production environments.

Prioritize teams that demonstrate understanding of enterprise security requirements, data governance, system uptime expectations, and organizational change management that ensure successful digital twin adoption beyond initial deployment.

Conclusion and Next Steps

Selecting an experienced digital twin development partner positions your organization to capitalize on real-time operational intelligence opportunities while ensuring high-quality delivery and project success. The top 5 companies outlined here represent proven expertise in digital twin development with specific capabilities across operational monitoring, simulation, training, and enterprise integration.

Treeview leads with enterprise-grade digital twin solutions deployed on spatial computing devices like Apple Vision Pro, Meta Quest, Android XR, 3D web and mobile. TechViz excels in collaborative visualization for engineering and industrial design workflows. Dassault Systèmes provides industry-defining enterprise platforms for full lifecycle digital twin management. Toobler offers flexible, custom digital twin solutions integrated with existing operational systems. Digital Twin Studios delivers specialized strategy, architecture, and implementation expertise for organizations building digital twin capabilities.

To Get Started

Define your digital twin project requirements including operational objectives, data sources, target platforms, key capabilities, performance expectations, and success metrics to guide development company selection

Contact 2-3 companies from the top 5 list for detailed consultations that explore your specific use case, data integration requirements, and operational objectives

Request proposals that outline technical approach, team composition, development methodology, timeline, pricing structure, and post-deployment support capabilities for informed vendor selection

Looking Ahead

Monitor digital twin platform evolution including advances in AI-powered analytics, edge computing integration, autonomous optimization capabilities, and expanding spatial computing interfaces. Consider pilot projects to establish development partnerships before full-scale implementation, positioning your organization for long-term success in operational intelligence, predictive maintenance, training, and enterprise-wide digital twin deployments.

Strategic digital twin investments provide significant competitive advantages for organizations ready to leverage real-time system modeling and simulation for enhanced operational efficiency, risk reduction, and data-driven decision-making across physical and digital operations.

FAQs About Digital Twin Development Companies

Common questions that businesses and organizations ask when evaluating digital twin development opportunities.

What makes digital twins different from standard 3D visualization?

Digital twins continuously synchronize with their physical counterparts through live data from IoT sensors, enterprise systems, and operational platforms. Unlike static 3D models, digital twins provide real-time operational intelligence, predictive simulation, and interactive monitoring capabilities that reflect current system state and enable data-driven decision-making.

How much does digital twin development cost?

Development costs typically range from $75,000 for single-asset monitoring twins or basic operational visualizations to $150,000-$250,000 for mid-scale projects with moderate complexity and multi-source data integration, and $300,000+ for complex enterprise-wide digital twin platforms with advanced features like predictive simulation, AI-powered analytics, spatial computing interfaces, and multi-system data synchronization.

Which industries benefit most from digital twin development?

Manufacturing and energy see the highest digital twin adoption, but enterprise applications across healthcare, construction, logistics, smart cities, and infrastructure increasingly leverage digital twins for operational monitoring, predictive maintenance, scenario planning, and training simulations. Any industry managing complex physical systems benefits from digital twin development capabilities.

Can digital twins integrate with existing enterprise systems?

Yes, digital twins can integrate with REST APIs, IoT platforms, SCADA systems, building management systems (BMS), ERP software, cloud platforms (AWS, Azure, Google Cloud), SQL databases, and custom backend services. Experienced digital twin development companies architect these integrations to enable real-time data visualization, operational monitoring, and business process automation.

What technical expertise should I look for in digital twin development companies?

Prioritize companies with high-quality real-time 3D engine proficiency (Unity, Unreal Engine), IoT integration experience, cloud infrastructure knowledge, proven data pipeline architecture capabilities, and track records in your specific application type (operational monitoring, simulation, training, or enterprise integration). Additional valuable capabilities include spatial computing interface development, AI/ML integration, and cross-platform deployment experience.

How long does digital twin development take?

Project timelines vary from 3-6 months for single-asset monitoring twins or basic operational visualizations to 6-12 months for mid-scale projects with multi-source data integration, and 12-18+ months for complex enterprise-wide digital twin platforms. Timeline depends on system complexity, data source diversity, simulation requirements, spatial computing interface needs, and enterprise integration scope.

What's the difference between a digital twin and a digital shadow?

A digital twin provides bidirectional data flow between the physical system and its digital representation, enabling both monitoring and control. A digital shadow provides unidirectional data flow from physical to digital, supporting monitoring and visualization without active control capabilities. Most enterprise implementations begin as digital shadows and evolve toward full digital twin functionality. In day to day conversation digital twins usually cover digital shadows.

What data sources do digital twins typically integrate with?

Digital twins commonly integrate with IoT sensors (temperature, pressure, vibration, flow), SCADA systems, building management systems, ERP platforms, MES (Manufacturing Execution Systems), CMMS (Computerized Maintenance Management Systems), weather APIs, energy management systems, custom operational databases and predictive AI models. The specific data sources depend on industry and use case requirements.

How do digital twin development companies handle data security?

Leading digital twin developers implement enterprise-grade security including encrypted data transmission, role-based access control, secure API authentication, network segmentation, and compliance with industry-specific regulations (HIPAA for healthcare, NERC CIP for energy). They architect digital twin platforms to meet organizational security policies and data governance requirements.

What kind of post-deployment support should I expect from digital twin development companies?

Leading digital twin developers provide ongoing support including system monitoring, data pipeline maintenance, platform updates, new data source integration, feature additions, performance optimization, security patching, and user training. Enterprise digital twin implementations typically include maintenance agreements covering technical support, system updates, and platform evolution roadmaps.

Can digital twins include AR/VR interfaces?

Yes, digital twins can be accessed through augmented reality and virtual reality interfaces that enable immersive system interaction. AR overlays provide contextual digital twin data on physical equipment, while VR enables full immersion in digital twin environments for training, simulation, and remote operations. Experienced development companies build spatial computing interfaces for Apple Vision Pro, Meta Quest, Android XR, and other XR platforms.

How do digital twin development companies ensure data accuracy?

Top digital twin developers employ sensor calibration validation, data quality monitoring, anomaly detection systems, physics-based modeling verification, and continuous accuracy benchmarking against real-world performance data. They implement data governance frameworks that ensure the digital twin accurately reflects physical system behavior within defined tolerance levels.

What are the key components of a digital twin platform?

A comprehensive digital twin platform includes five core layers: data ingestion (IoT connectivity, protocol translation, data pipeline management), 3D environment (real-time rendering, spatial modeling, visual fidelity), simulation engine (physics modeling, scenario testing, predictive analytics), interaction layer (dashboards, spatial computing interfaces, collaboration tools), and enterprise integration (API connectivity, system interoperability, business process automation).

How do organizations measure digital twin ROI?

Organizations typically measure digital twin ROI through operational efficiency gains (reduced downtime, optimized maintenance schedules), risk reduction (fewer safety incidents, reduced rework), training cost savings (faster competency development, reduced physical training needs), and decision-making improvements (faster response times, data-driven planning). Leading digital twin development companies help define success metrics during project scoping to ensure measurable value delivery.

Which major companies use digital twins for their operations?

Digital twins power operations at organizations including Siemens, GE, BMW, Shell, Boeing, NASA, Singapore's Smart Nation initiative, and thousands of other enterprises across manufacturing, energy, aerospace, and infrastructure sectors. This widespread adoption demonstrates digital twin capabilities for projects ranging from single-asset monitoring to city-scale infrastructure management.